About us

Work towards perfection

WanDah Electric Heater Co., Ltd. was found in 1970 by president, Mr. Dave Chen. We specialize in aluminum alloy, zinc and magnesium alloy melting, holding, heat treatment, ceramic and glass kilns, electric heaters, and thermocouples. As an industry pioneer in Taiwan, we have expanded our business in Asia and America.

For the past few decades, we pursuit perfection by continuous researching, developing new technology and innovating, we are proud to own several patented products. WanDah provides variety of customized products to meet clients different needs. We stand as an industry pioneer because we have competitive pricing, professional and experienced working team, advance facilities, timely delivery, well after sales service, we are able to provide quality products which are comparable to European and Japanese brands.

Our goal is to work towards perfection, we will continue to explore new technology as well as develop new environment friendly products.

Company Profile

1970 Establishment of Wan Dah Electric Heater Co., Ltd.

1972 Resistance Heated Crucible Melting and Holding Furnaces

1973 Salt Bath Heat Treatment Furnaces

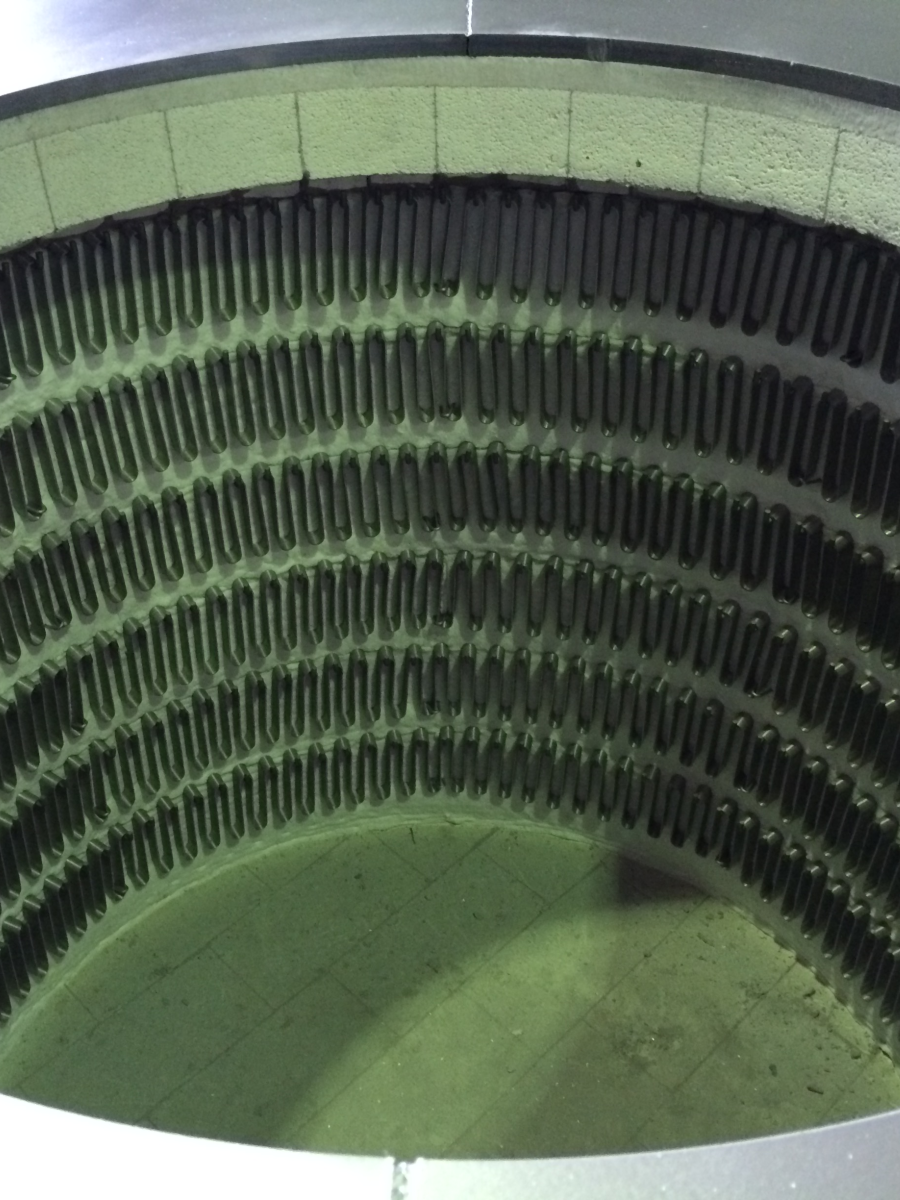

1974 Top Loading and Tunnel Enameling Ceramic Kilns

1978 Purchasing of the land for new factory in Peitou district Taipei

1981 Tunnel Type Ceramic Kilns

1982 Increasing in capital and starting the construction of the new factory site

1983 Moving to new factory and starting production of Shuttle Type Ceramic Kilns

1984 Reverberatory Melting Furnaces and Metal Heat Treatment Furnaces

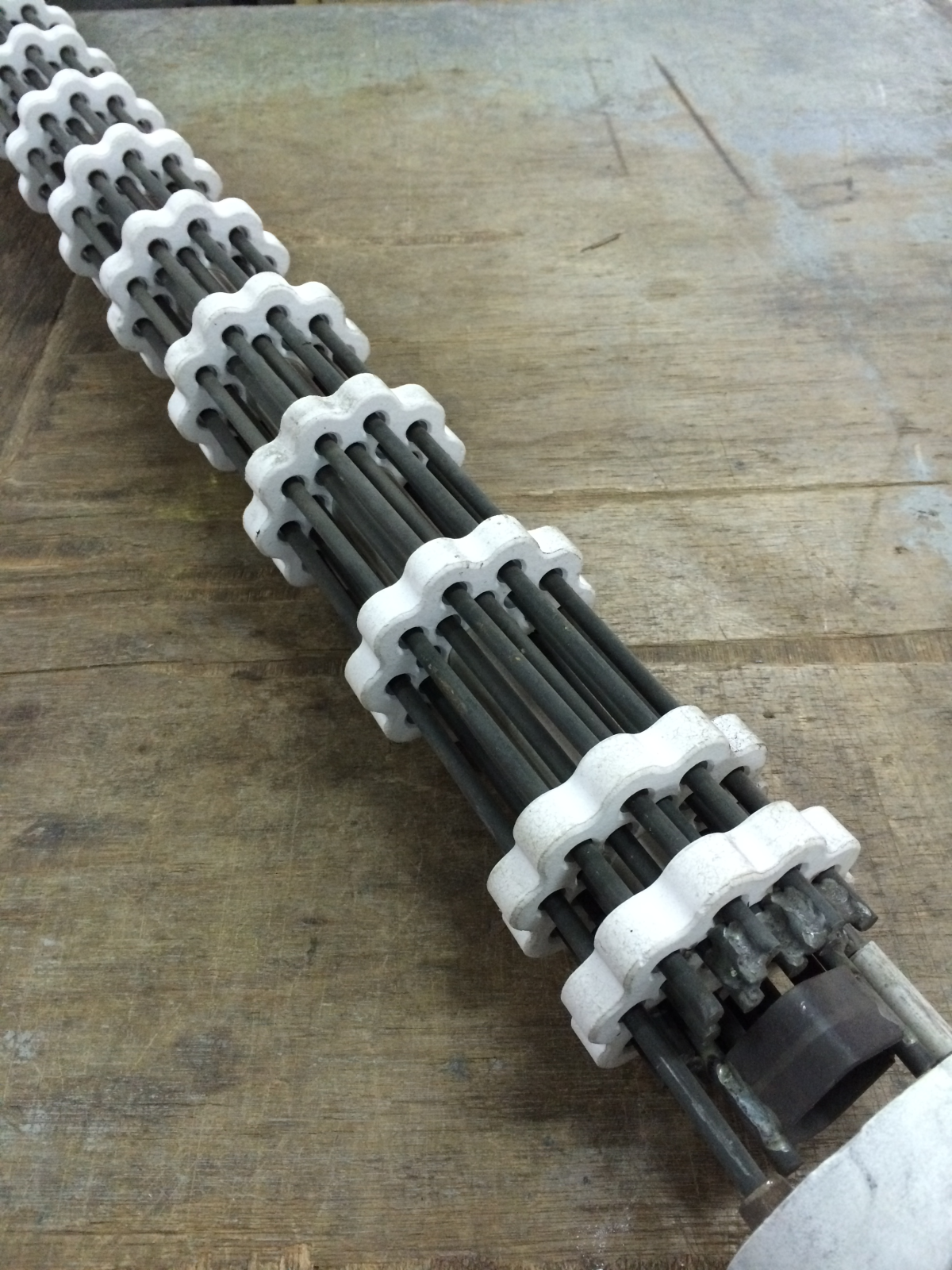

1985 Resistance Heated Melting and Holding Furnaces with Carbon Crucible for Low pressure casting

1987 Tower Type Aluminum Alloys Melting Furnaces

1987 Electric Non-Crucible Low Consumption Holding Furnaces

1988 340kg Tilting Resistance Heated Crucible Aluminum Alloys Melting Furnaces

1988 pgraded of Tunnel Type Ceramic Kilns

1990 585kg Tilting Resistance Heated Crucible Aluminum Alloys Melting Furnaces

1991 Obtainment of patent design #64760 for Air Prevention System for Shuttle Type Kilns from MOEA Taiwan

1991 585kg Tilting Aluminum Alloys Melting Furnaces with Crucible available in gas or oil burner

1992 330-500kg Oval Resistance Heated Crucible Aluminum Alloys Melting and Holding Furnaces

1993 Obtainment of patent design #86409 for Anti-Block of Burner Nozzle from MOEA Taiwan

1993 Upgraded model for Tower Type Aluminum Alloys Continuous Melting Furnaces

1994 Obtainment of patent design #96675 for Molten Metal Container from MOEA Taiwan

1997 T4/T6 Instant Drop Aluminum Alloys Heat Treatment Furnaces

1998 Zinc Alloys Electric Melting Holding Furnaces

2000 Tilting Type Aluminum Alloys Continuous Fast Melting Furnaces

2002 Tilting Zinc Alloys Melting Holding Furnaces

2002 Central Tower Type Zinc Alloys Melting Holding Furnaces

2006 Purchasing of the land for 2nd plant in Peitou district Taipei

2014 Purchasing of the land for 3rd plant in Danshui district Taipei

2015 Second Generations Electric Non-Crucible Low Consumption Holding Furnaces

2016 New immersion electric non-crucible low consumption holding furnaces

2017 Third Generations Electric Non-Crucible Low Consumption Holding Furnaces

2019 Trolley Twin Switch Resistance Heated Crucible Melting and Holding Furnaces

解決方案

設備升級、產線規劃、效能優化、品質保證、負責安心、維修服務、自動化方案

品質保證、負責安心、維修服務、設備升級、產線規劃、全廠佈局、自動化方案。

五十多年來的專注本業,培育出萬達專業維修團隊、高效完善的售後服務,不僅止於對萬達爐具設備負責;我們對其他品牌爐具也提供維修服務,無論是何種熔解、保溫、亦或是熱處理本源於同宗。萬達專業維修服務,有口皆碑。

豐富的專業技術結合先進高品質材料,生產製作出高品質產品,從電熱器至爐具設備,我們堅持自行生產製作,萬達就是品質保證。

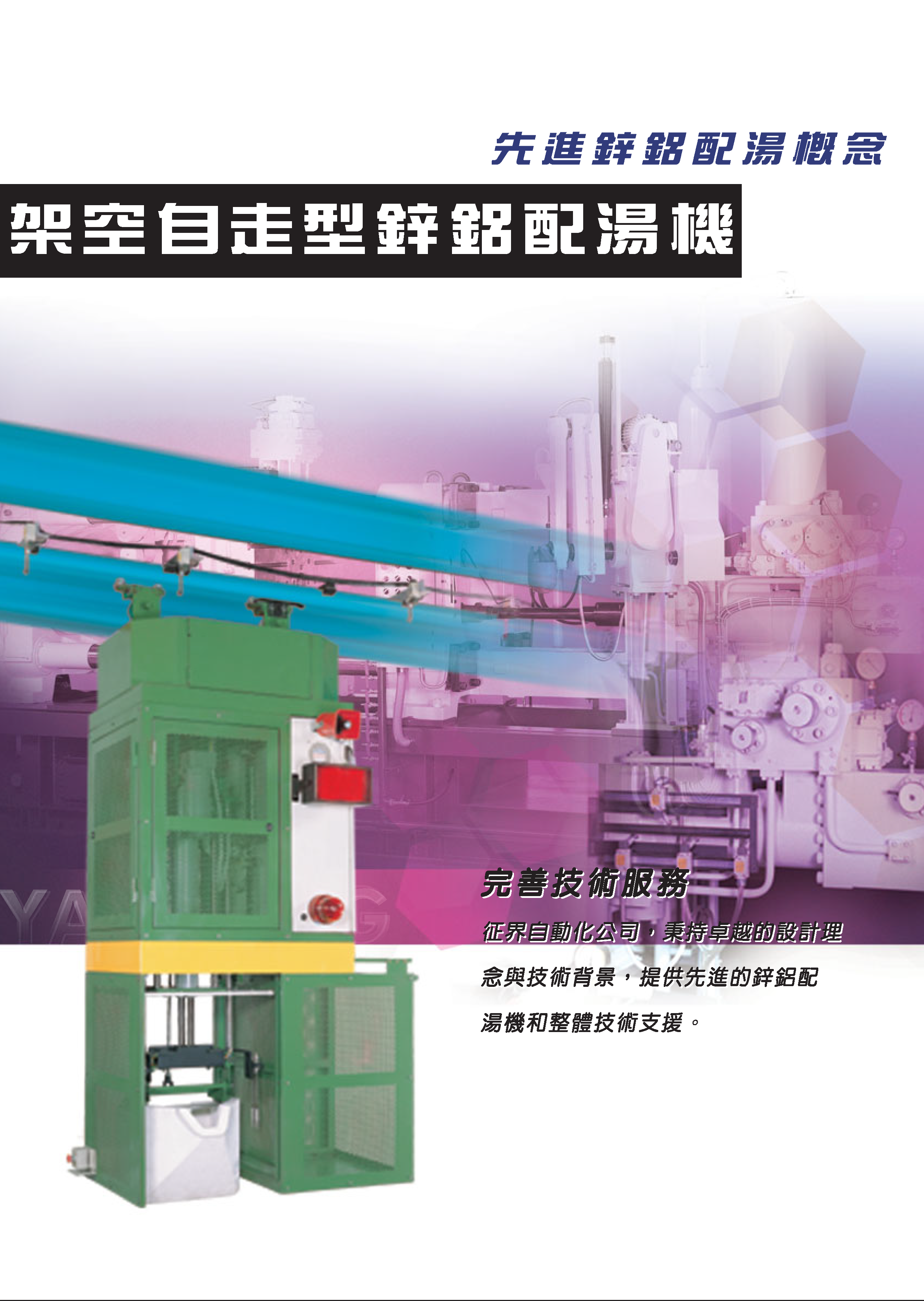

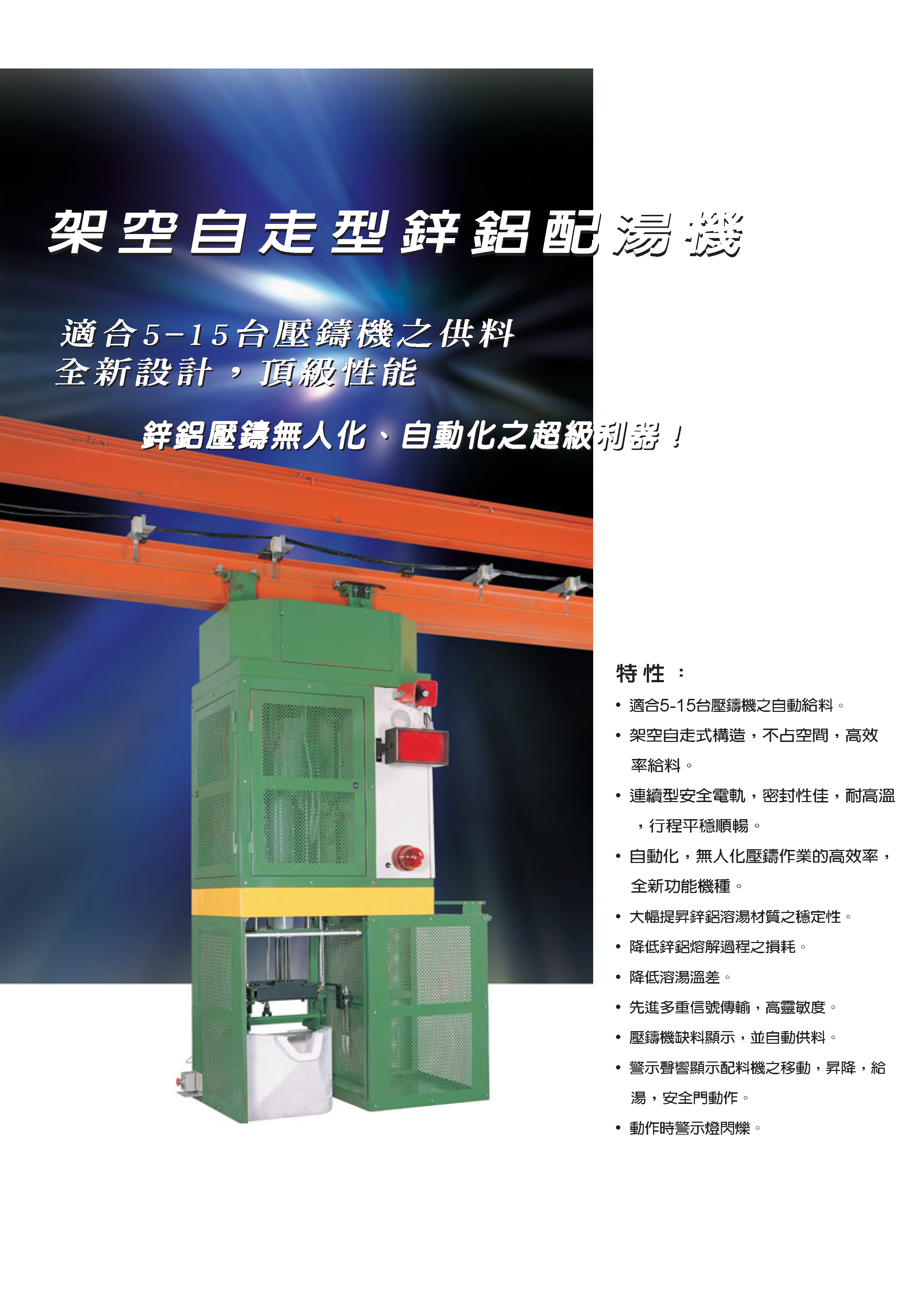

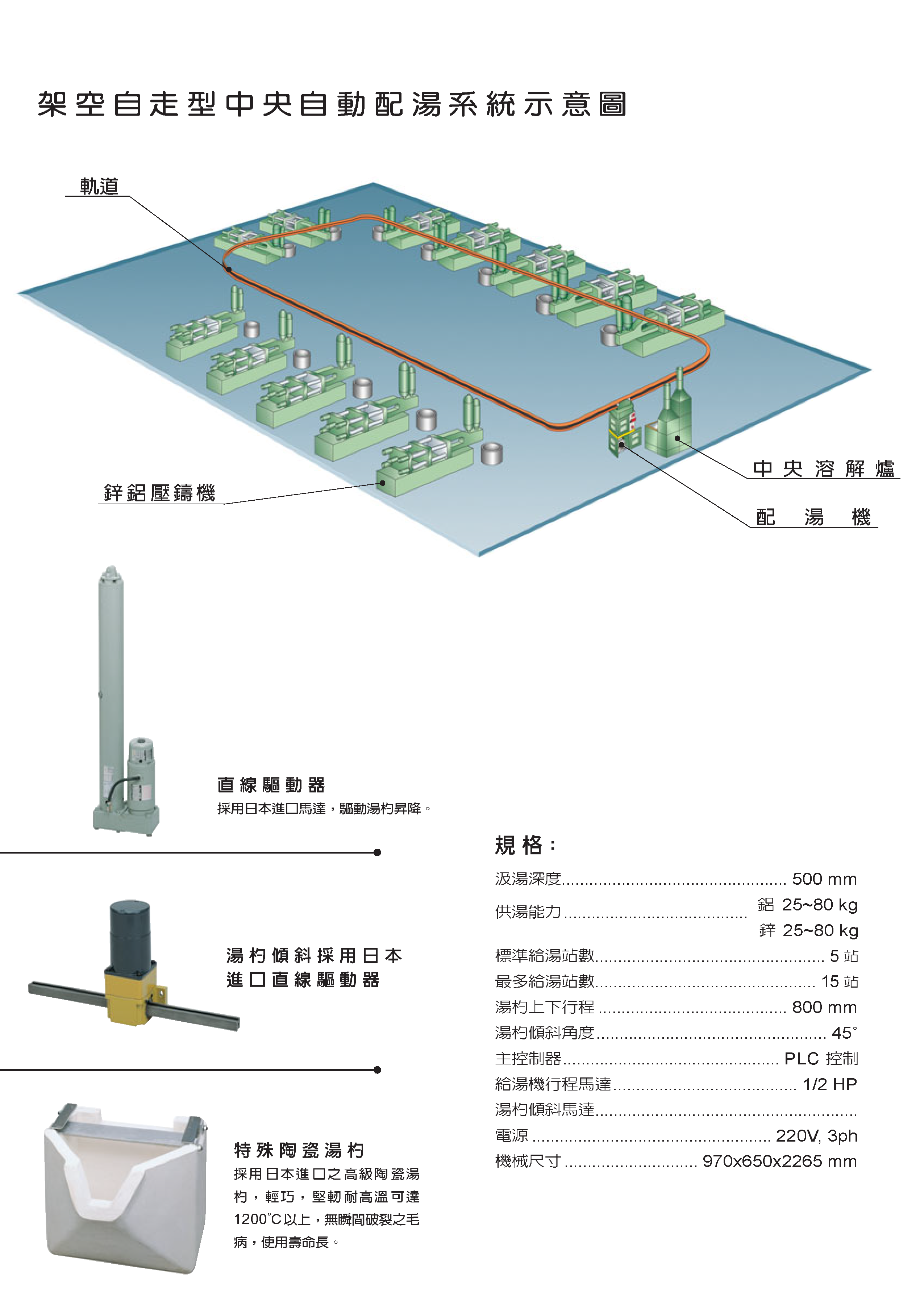

伴隨著產業不斷提升,我們也提供設備升級方案,協助您在預算內發揮最大設備效能,進而提高產品良率。亦或是協助自動化方案規劃;如全自動配湯系統,一次滿足您全廠補料需要,高品質、低損耗、省人力、降成本,高效安全、不佔空間,壓鑄溫度條件穩定,鑄件品質掌控度提高。

如果對萬達產品有進一步興趣,無論您身處何地,我們可以安排您就近參觀我們分布海內外的客戶,實地了解萬達爐具設備。

我們不以名牌自許,但以品質屹立業界。

“ 7-24-365 ” 我們隨時都在

傳統一對一熔解配置, 常因人工補料所產生的快速溫降現象, 導致壓鑄溫度條件不穩定, 鑄件品質無法準確掌控. 採用中央熔解爐並搭配自動配湯系統則無溫差顧慮, 同時節省人力降低熔解原料損耗. 一般熔解爐為開放式加熱, 熔解損耗比約3% - 5%, 熱能傳導率15%, 而中央熔解系統係採封閉式反射加熱法, 阻斷大面積熔湯直接與空氣接觸, 熱氣平均分佈, 均溫度佳熔解迅速且原料損耗低。

高效自動化、不佔空間

* 多站點補料設計.

* 架空式設計, 不佔空間.

* 連續型安全電軌, 密封性佳, 耐高溫, 行程平穩順暢.

* 多重信號傳輸, 靈敏度高.

* 缺料信號顯示通知, 自動取湯前往補料.

* 配湯機動作同時發出警示聲響與閃爍警示燈, 安全性高.